Xtra-High Pressure Advantage

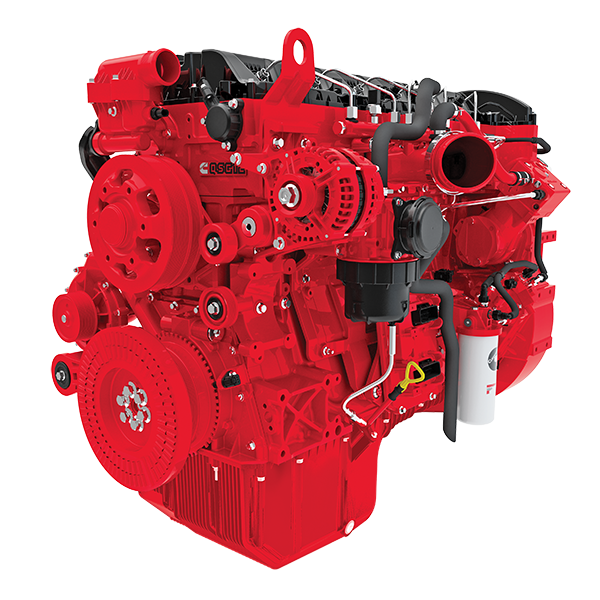

The QSG12 incorporates Cummins Xtra-High Pressure Injection (XPI) fuel system, derived from the larger and more powerful QSX15 Tier 4 Final engine. Although scaled down in size for the 12-liter platform, the XPI fuel system retains all the robust, heavy-duty characteristics of the system, proven up to 675 hp (503 kW) on the 15-liter.

With multiple injection events driven by high-precision Cummins electronic controls, the XPI fuel system contributes to a very impressive peak torque for the QSG12 of 1700 lb-ft (2305 N•m), together with a torque rise as high as 60 percent available. These attributes enable the QSG12 to deliver exceptionally fast response to increasing load factors from low engine rpm.

XPI在增强发动机社交性方面发挥了重要作用,噪音较低,振动较小,动力传递更平滑。使用后齿轮火车还通过将振动和降低噪声降低至少1 dba来有助于整体发动机的改进。

Ultra-Clean DPF-SCR Aftertreatment

The QSG12 is designed as a fully integrated air intake to exhaust aftertreatment package ready for drop-in machine integration. Designed and manufactured for the 12-liter engine by Cummins Emission Solutions (CES), the aftertreatment combines a Diesel Particulate Filter (DPF) with Selective Catalytic Reduction (SCR) to achieve an ultra-clean exhaust.

Based on Cummins Tier 4 Interim/Stage IIIB experience, the DPF operates as a near passive device, with automatic active regeneration occurring less than 1 percent of engine running time. The use of a DPF in the exhaust stream provides the QSG12 with an additional margin of Particulate Matter (PM) emissions control at higher engine loads, to realize better transient response. The heavy-duty DPF has no impact on equipment operation, with the machine continuing to work as normal during automatic active regeneration.

The SCR system developed by Cummins for Tier 4 Final/Stage IV is a next-generation design with a copper zeolite-based catalyst capable of over 95 percent conversion of Oxides of Nitrogen (NOx), able to operate more efficiently at lower temperatures, with advanced sensors providing full closed-loop control. Using an Ecofit™ UL2 doser supplied by CES, the Diesel Exhaust Fluid (DEF)/AdBlue dosing levels are minimized due to a high precision injection spray pattern with more effective fluid decomposition.

When the cost of DEF required for the SCR system is combined with the cost of fuel consumed, the overall fluid operating cost of the QSG12 for Tier 4 Final remains lower than that of the previous QSX11.9 engine at Tier 4 Interim.

康明斯排放解决方案experience of integrating DPF and SCR technology as a single system is unmatched in the industry, with almost 450,000 Cummins engines produced with this combined aftertreatment.

为极端而建

The QSG12 is built ready to deal with the toughest operational extremes experienced by off-highway machines. Even working under high load factors, the QSG12 will achieve the same legendary life-to-overhaul as that achieved by the QSM11 at Tier 3 and Stage IIIA. Operators of QSG12-powered machines can expect – and may exceed – 12,000 hours before overhaul. Significantly, no midlife engine overhaul is required.

康明斯DPF-SCR后处理系统能够承受严重的冲击负荷和振动,其设计具有相当于发动机的耐用性。此外,QSG12只需安装标准的油箱,就可以以45度的角度工作。

To provide maximum engine protection, particularly when working under dusty conditions, the QSG12 features an integrated Cummins Direct Flow™ air filtration system developed for Tier 4 applications. The Direct Flow air filter provides greater dust-holding capacity in a smaller package, with filter element change intervals at least twice that of conventional air filters. The filter also features an embedded smart sensor to fully integrate air-intake flow with the engine combustion.

A two-stage fuel filter system for the QSG12 features the latest NanoNet™ media from Cummins Filtration, to ensure that the XPI fuel injection system is fully protected against fuel contaminated with hard particles. NanoNet media trap almost 99 percent of all particles as small as 5 microns, so that the filter works more effectively for longer, with less fuel-flow restriction.

康明斯过滤的专业知识还扩展到高效合并过滤器,以消除曲轴箱烃排放和油雾,进一步增加了QSG12的清洁引擎凭证。

Machine-Adaptive Features

QSG12专门配置了一系列机器自适应功能,以促进各种应用程序范围内的机器集成。例如,康明斯浪费的涡轮增压器可在后部,低安装位置或正面的中置位置提供,以提供增加的安装灵活性。

Other useful options include a front power take-off (FEPTO) with up to 564 lb-ft (630 N•m), a rear power take-off/hydraulic drive (REPTO) with up to 516 lb-ft (700 N•m) and a side-mounted drive for a hydraulic pump. For machines requiring engine braking, a compression brake option is available, or an integral exhaust throttle can be utilized.

QSG12使用的DPF-SCR超清洁后处理系统很容易适应每个特定的机器安装空间,这是因为模块化格式可在水平和垂直方向上具有多种配置。

QSG12中孔发动机完全补充了QSX15大孔发动机的补充,以将康明斯重型功率范围扩展到最高675 hp(503 kW)的第4层/阶段IV,这两个发动机都共享类似的DPF-SCR,lol电子竞技技术。